Ohio University researchers co-authored a study proposing a new take on energy-efficient window design using energy-saving glasses and films that are cost-effective and block excessive solar infrared radiation.

Dr. Lucas Besteiro, a former post-doctoral researcher at OHIO, Visiting Research Scholar Dr. Xiang-Tian Kong, and Dr. Alexander Govorov, Distinguished Professor of Physics, published “Plasmonic Glasses and Films Based on Alternative Inexpensive Materials for Blocking Infrared Radiation” in Nano Letters, a journal of the American Chemical Society, a publication with a high impact factor. Besteiro is currently a researcher at INRS-EMT, University of Quebec, in Montreal, Canada. Other co-authors are Professor Zhiming Wang of the University of Electronic Science and Technology, in Chengdu, China, and Professor Federico Rosei, also of INRS.

- Their research was featured in a story headlined “Plasmonic windows by design” at nanotechweb.org.

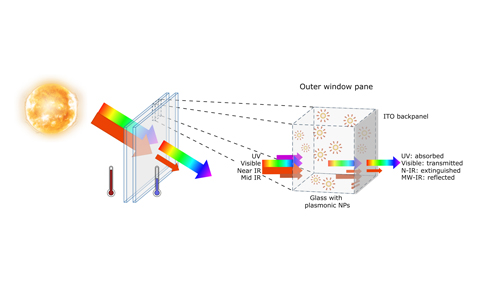

The authors provide a theoretical analysis and guidelines for the planning stage of energy-saving materials used in window manufacturing. A key feature of the proposed windows is to block infrared radiation (IR), which carries much of the energy coming from the sun (approximately 53 percent), while letting most of the visible light pass, so that people can see clearly through the windows. Additionally, they would provide lighting conditions that are friendlier to the human eye than the ones provided by artificial lighting.

Energy-saving windows are well known and already available in the market. They block part of the solar radiation and prevent it from entering the space that they enclose, thus keeping the space at a lower temperature and reducing the need to cool the space with air conditioning or other means.

The authors propose alternative methods and materials to create better low-emissivity windows, using plasmonic nanoparticles of different shapes and materials. A plasmonic nanoparticle is one in which light excites collective electronic oscillations, and occur mainly in metallic nanoparticles. These collective excitations are different than single-electron transitions, and they are particularly strong in their interaction with light, so that plasmonic nanoparticles are very effective in creating novel optical materials.

Designing such plasmonic composite glasses requires taking full advantage of the different parameters that define the nanoparticles (both material and geometrical properties of the nanoparticles). The authors compute the performance of solar plasmonic glasses incorporating a transparent matrix and specially shaped nanocrystals, and this performance depends on the shape and material of such nanocrystals. Glasses designed with plasmonic nanoshells are shown to exhibit overall better performances as compared to nanorods and nanocups.

“We use nanorods, nanoshells, and nanocups in our design,” explains Besteiro. “These three are different geometries of nanoparticles, which can be fabricated in sizes ranging from tens to several thousand nanometers (one human hair has a thickness of tens of thousands of nanometers), and each of them can be made using different materials. The shape of rods is self-explanatory, being straight cylindrical rods; the shells are hollow spheres; and nanocups could be thought of as half nanoshells, they look a little bit like having the shape of a cereal bowl.”

One way to fabricate nanoparticles is to form them by the condensation of a given material, which is made available in gas form. These gas-phase fabrication methods stand in contrast with other common families of techniques such as liquid-phase methods (with chemical reactions occurring in a solution) or surface growth in a vacuum. They offer some advantages because they are relatively inexpensive and scale well, and they avoid some difficulties with particle dispersion that arise in liquid-phase synthesis. Then, synthesis of plasmonic nanoshells and nanocups is technologically feasible using gas-phase fabrication methods.

The computational simulations were performed for noble metals (gold and silver) as well as for alternative plasmonic materials (aluminum, copper, and titanium nitride). Inexpensive plasmonic materials (silver, copper, aluminum, and titanium nitride) show an overall good performance in terms of the commonly used figures of merit of industrial glass windows. Together with numerical data for specific materials, the authors provide a set of general rules for designing efficient plasmonic IR-blocking media, which are good candidates for the creation of cheap optical media, to be used in energy-saving windows in warm climates’ housing or temperature-sensitive infrastructure.

A low-emissivity window is a passive cooling system designed to block much of the solar spectrum while remaining transparent to visible light, thus reducing the amount of heating due to solar irradiation. This paper proposes to realize such systems by integrating a mixture of semiconductor and plasmonic nanoparticles in the outer panel of the window, blocking most of the UV and near IR solar radiation. Additionally, a conducting back panel is used to reflect mid and long wave IR radiation coming both from the outside and from the emission of the heated nanoparticles. The authors explore the use of a range of materials and shapes for the plasmonic nanoparticles, seeking to obtain good window performances with inexpensive materials. (Illustration: Lucas Besteiro)

The main venue for this kind of technology, Besteiro says, could be any building that hosts human activity, where it is desirable to provide natural illumination while keeping it at a comfortable temperature. Within such generally stated case, some infrastructure requires a stricter temperature control, such as server farms or certain laboratories. While it is unrealistic to think that these kinds of windows are an alternative to stronger insulation methods (walls, for instance), their usage for whatever degree of window arrangement that these buildings have will reduce their overall power consumption.

“The construction industry will likely find this design of interest,” Besteiro notes. “It adds to the range of tools that can be used to passively cool a building, and at a potentially lower price than current alternatives. This will hopefully reduce the investment required to install passive cooling in our houses, thus offsetting the financial imbalance between this approach and that of using active, energy-consuming cooling methods. Of course, this application can be extended to other sectors; such as the automotive industry. A car that uses less AC while driving under the sun will have a better mileage. This is part of the global effort to use nanoscale tools to create significant improvements to daily life.”

Comments